2 0 2 2

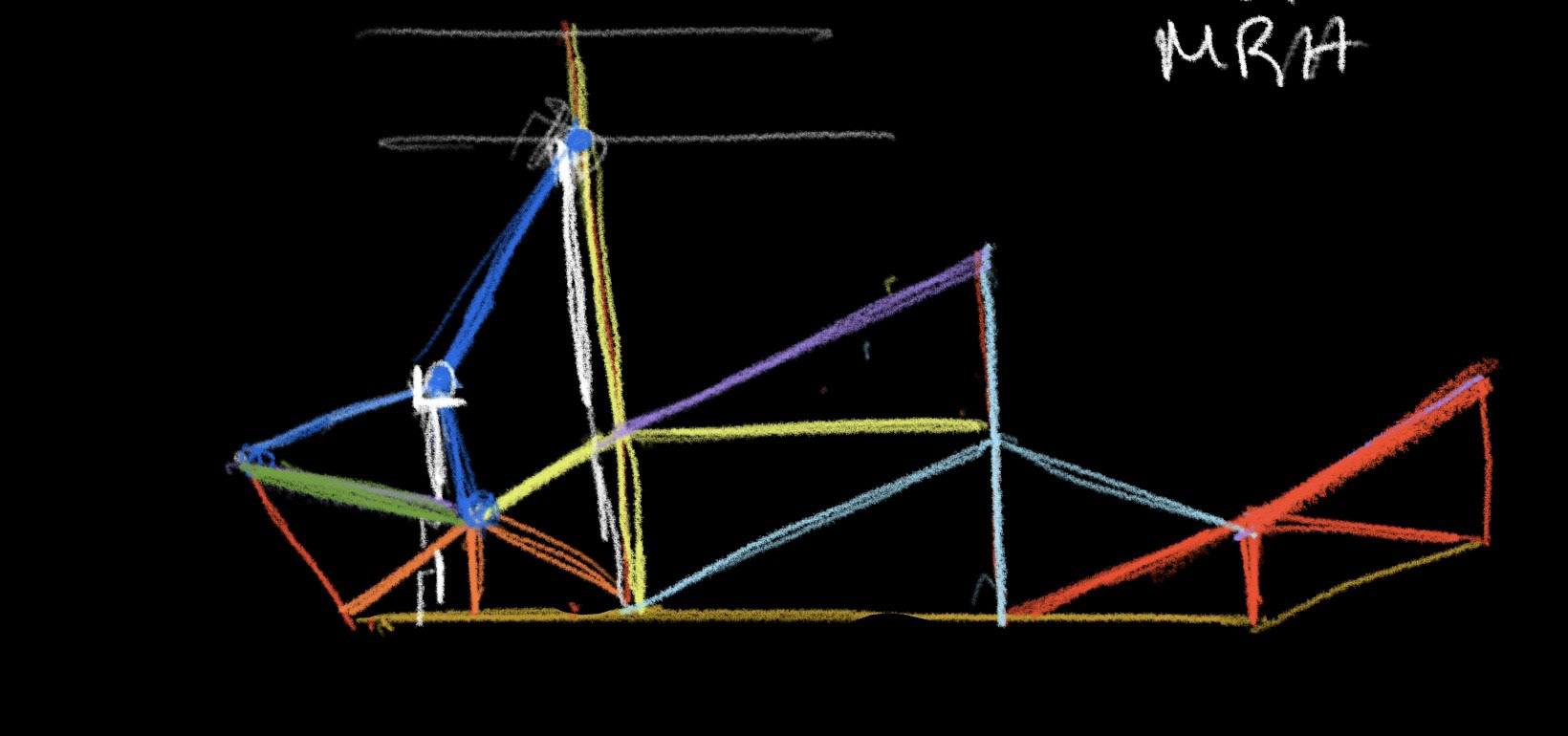

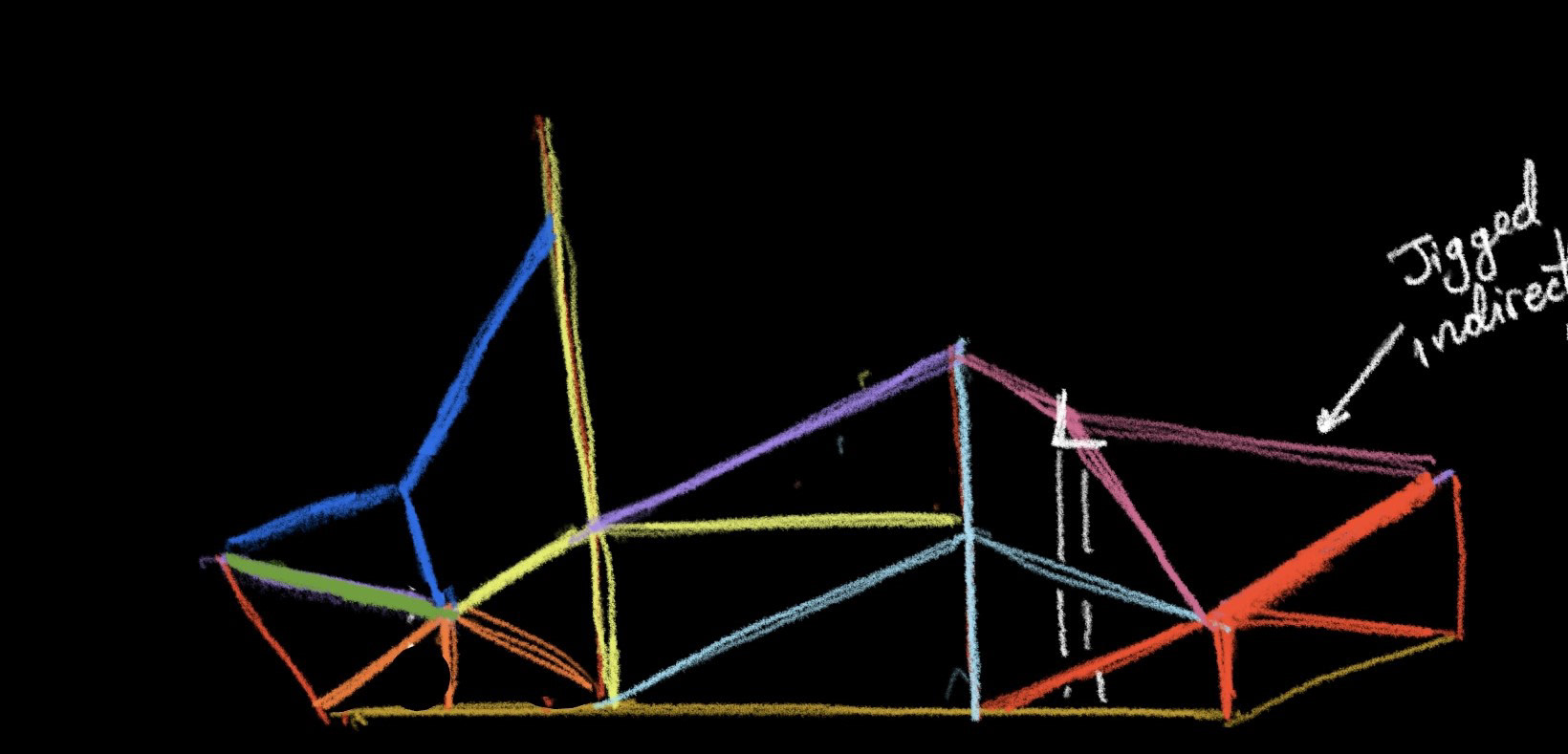

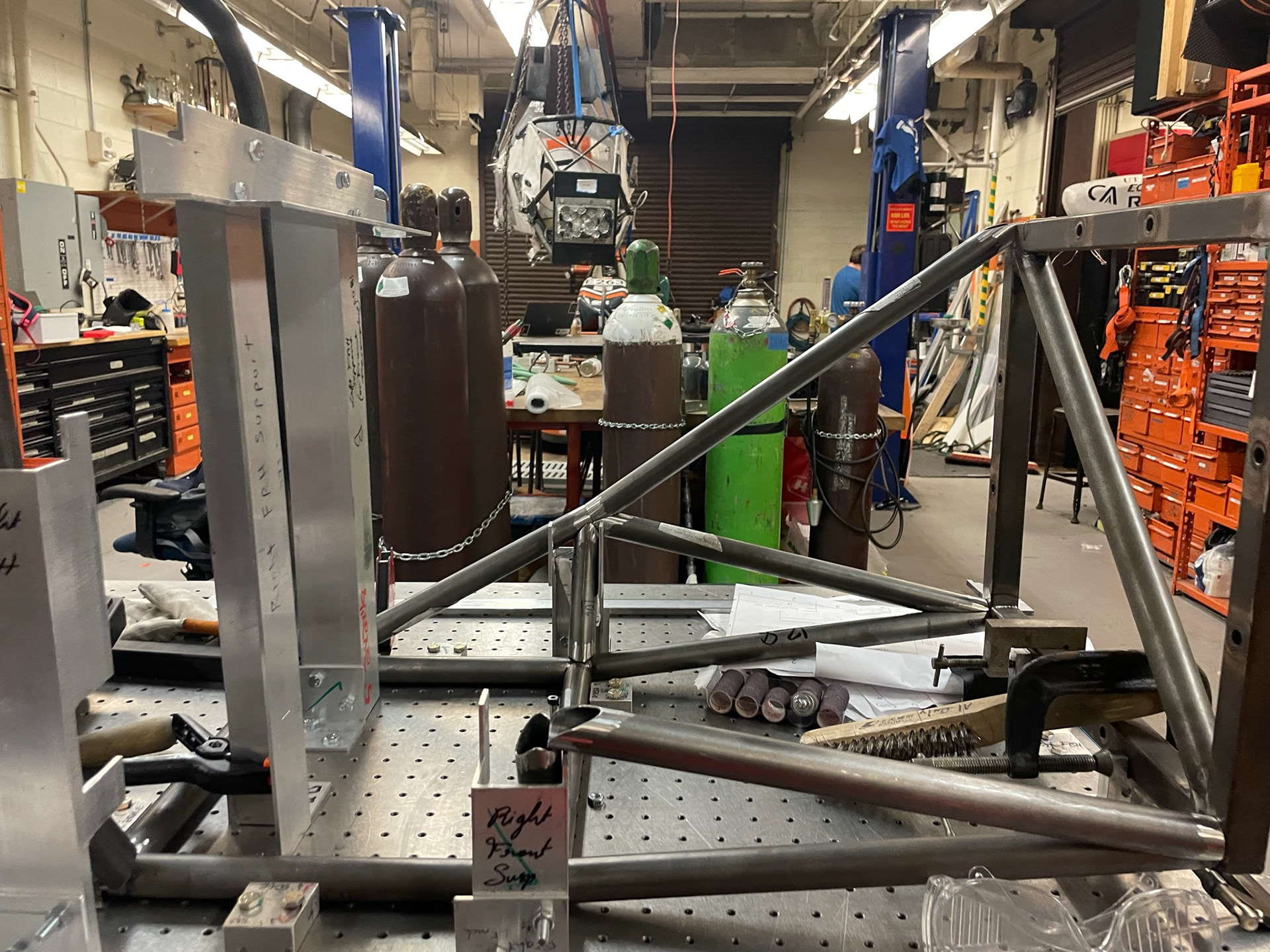

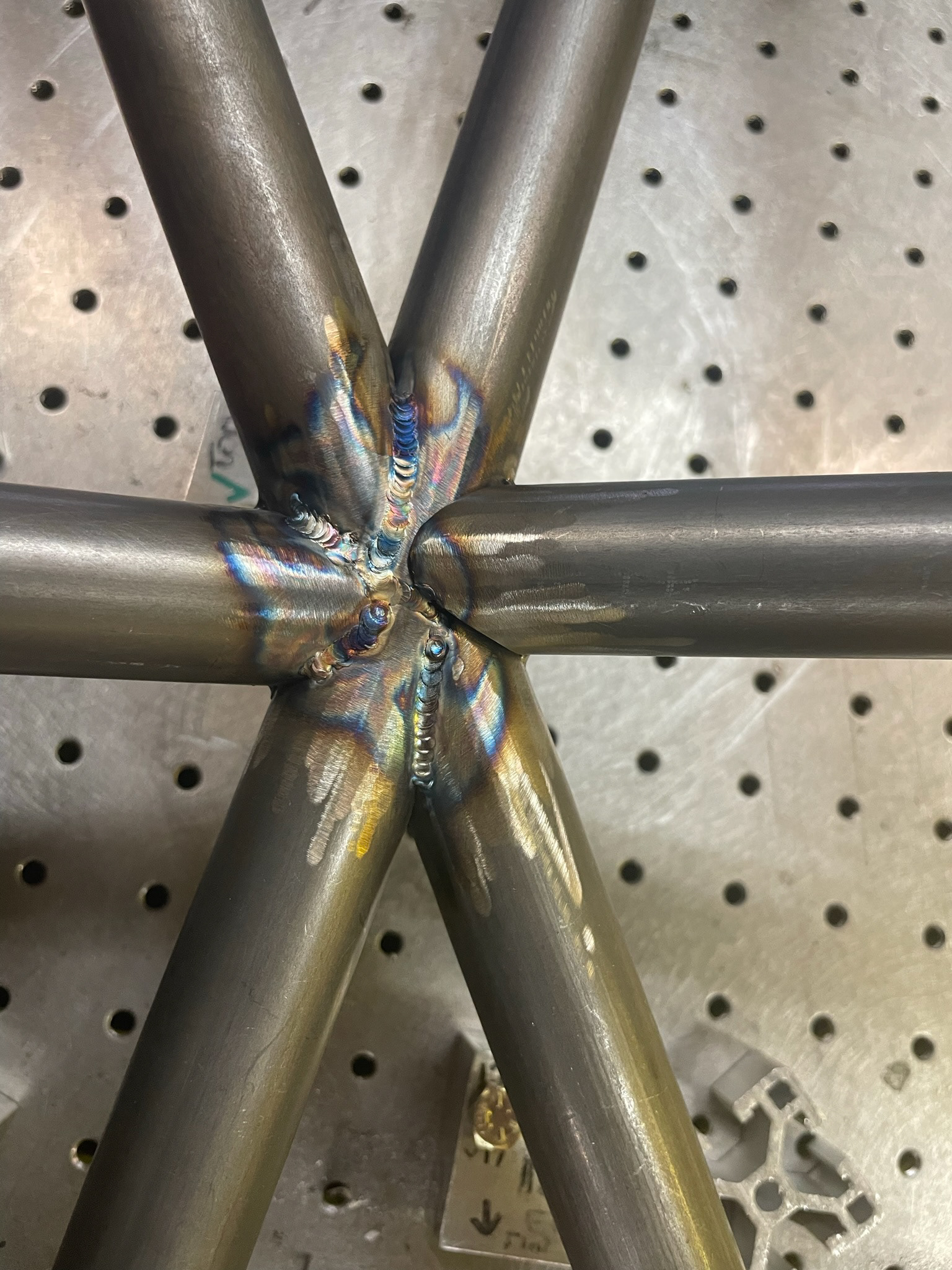

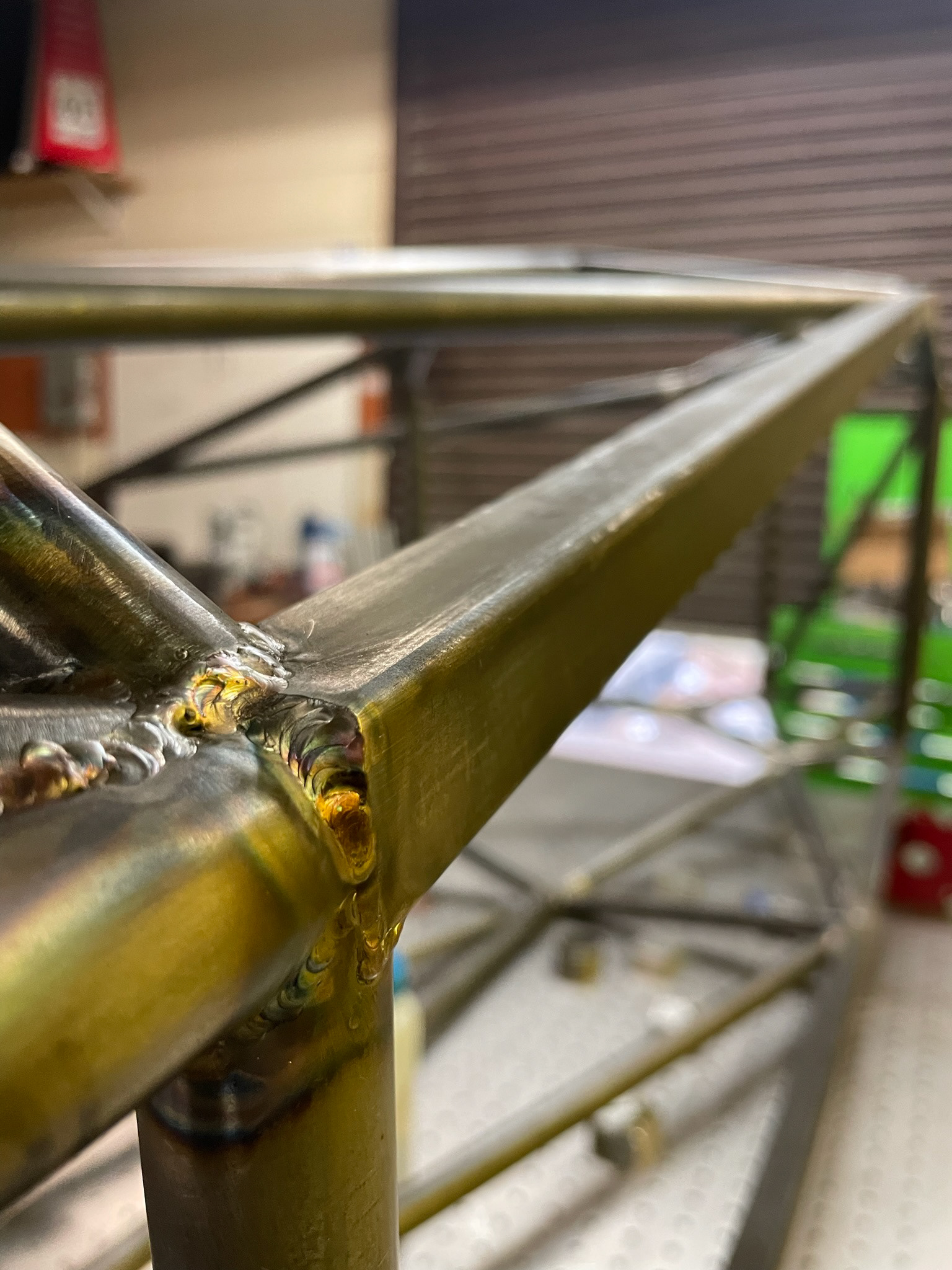

I began my journey with UT Austin's Formula electric team in January of 2022 as a member on the frame team. Learning to TIG weld on our steel frame helped me develop an understanding of the frame's design and how it effectively integrated the components of every system, accommodating their needs and adjusting to best support each component accordingly.

L e a r n i n g s

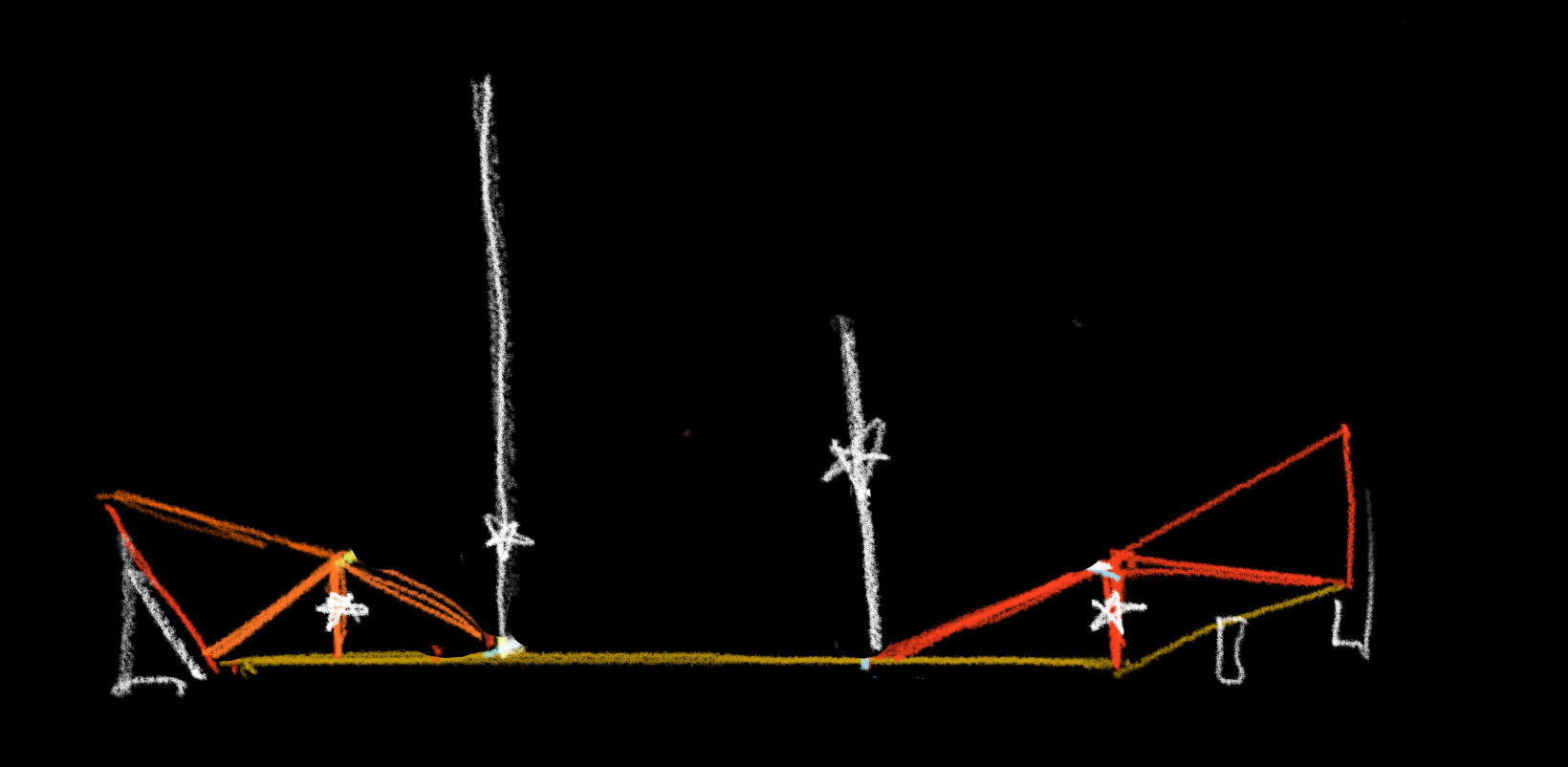

The jig we used to weld our 2022 chassis was made of 1/4-inch laser-cut wood panels that slotted together. The pros of this method were its low cost and fairly low design and manufacturing time. Following are some considerations we made with the design of our 2023 jig as a result of the experience of using this one.

An assembly plan is necessary. The jig should be designed to be both manufactured and used. This was something we hadn't foreseen and led to an extensive assembly process that required us to puzzle the frame tubes and jig together at the same time

Not all tubes need to be constrained by the jig. Many tubes were held by over three panels and at an additional two points (one on either end of the tube). This resulted in our frame being over constrained which consequently led to tolerance stack-up. Due to a very highly triangulated frame, many tubes could be entirely jigged by other tubes, which we looked into incorporating in our design for this year.

We saw the importance of prioritizing gap minimization. Over constrainment of the frame tubes (and partially our welding order) contributed to these gaps which led to some heat-soaked and filler-full welds. Heat control during a weld is especially important with 4130 chromoly, the material we chose for our frame. It has a higher strength-to-weight ratio than mild steel (1020 was our other material consideration) but is far more brittle. When heated and rapidly cooled, martensite (an especially brittle structure) forms which decreases the amount of force required to shatter the frame.

The process of designing this year's frame jig involved the consideration of alternative materials such as aluminum, steel, athicker wood. Though the material selection made our laser-cut wood jig cheap, fast, and easy to manufacture, deflection and warping both became issues that could have also contributed to tolerance stack up.

We wanted the jig to be easy to use in order to improve the quality of the welds themselves. Jig components on the inside of the frame and panels that surrounded the tubes Panels on the inside of the frame Challenging to weld around the panels made

Having a disassembly plan could help to minimize errors with tube location. Though rather fun it was not ideal to have to smash the wood panels after. This could bump tubes that were only tacked out of alignment

2 0 2 3

R e d e s i g n

A s s e m b l y P l a n

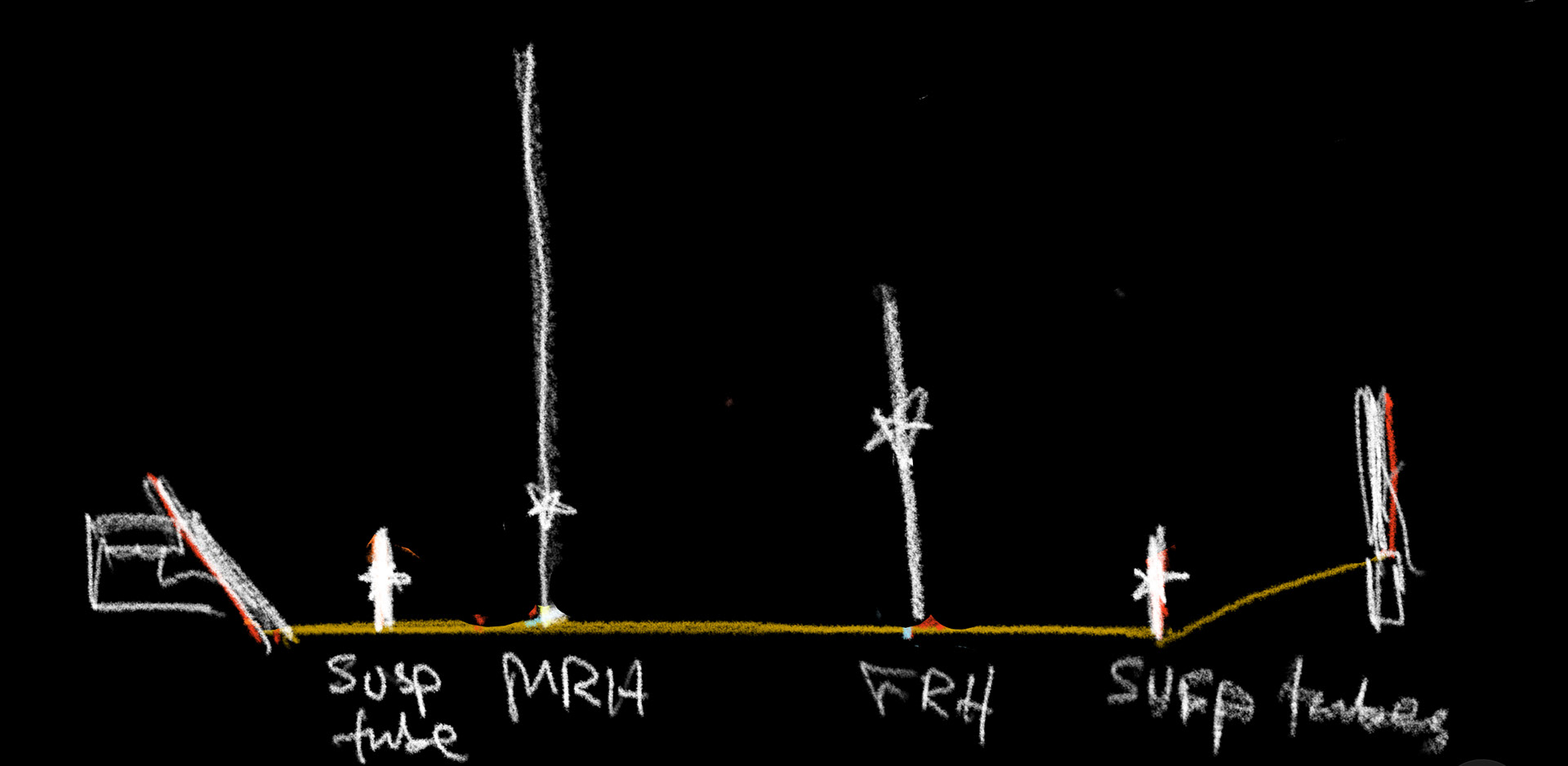

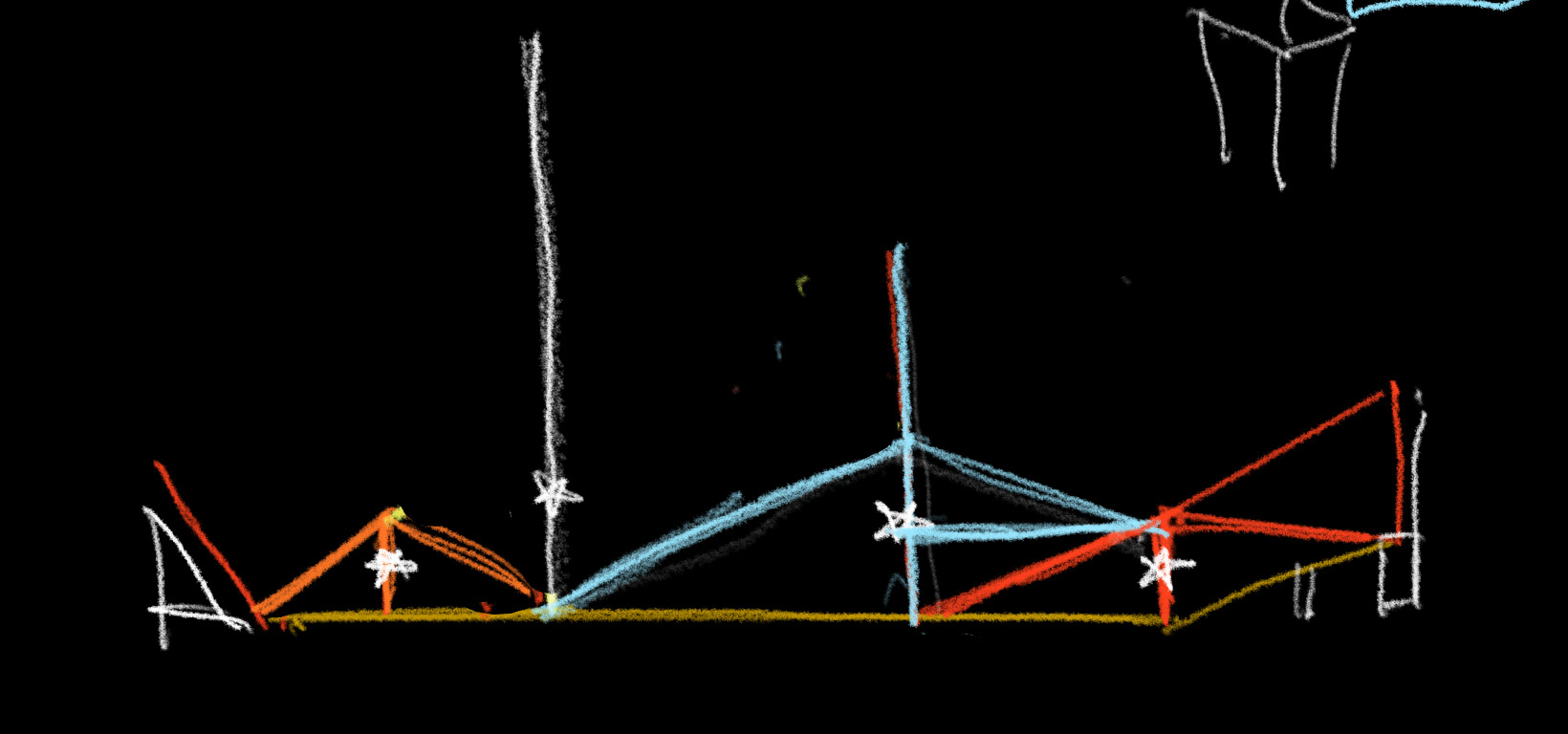

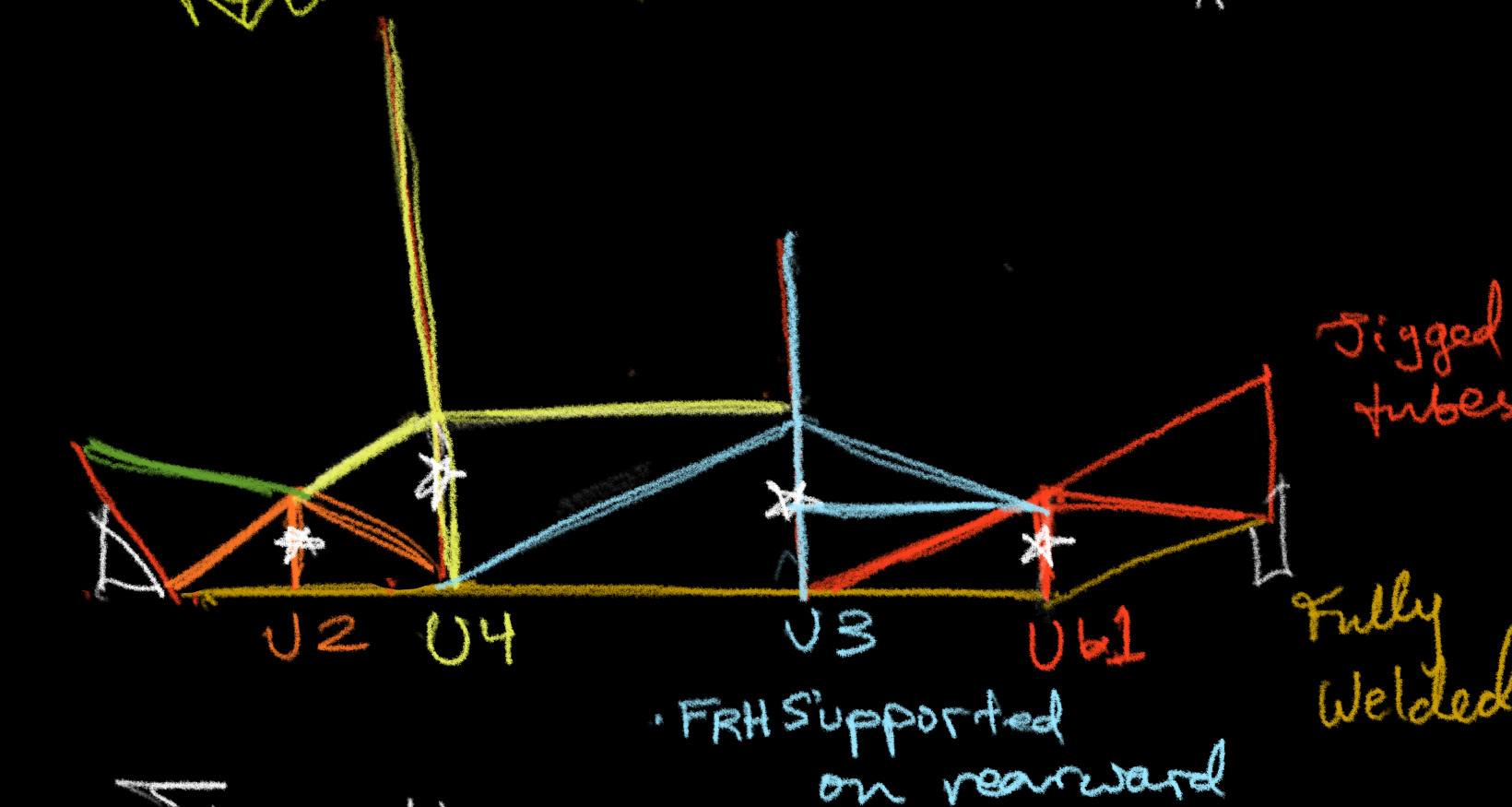

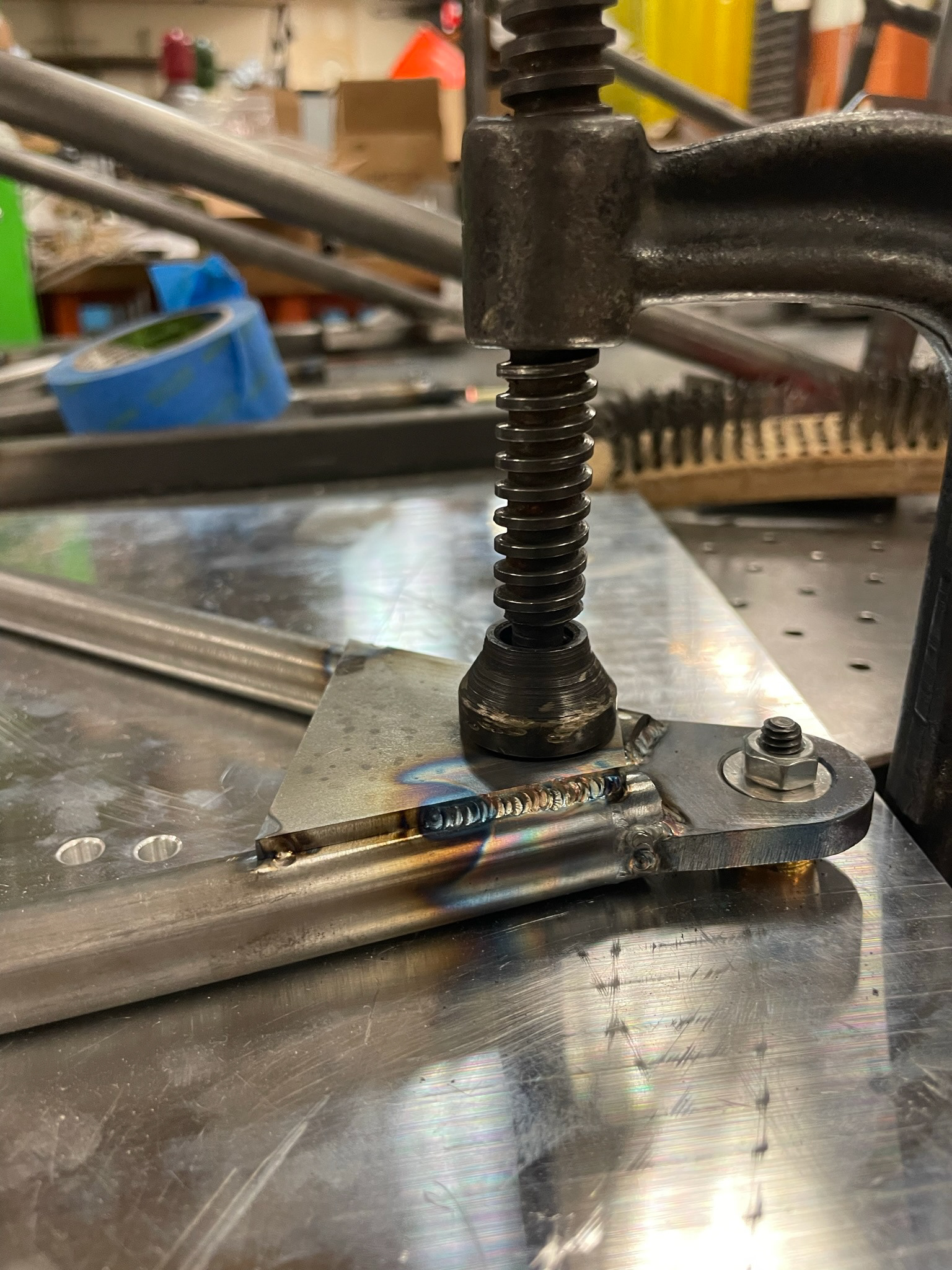

Our assembly plan included the order in which the frame tubes were assembled along with their respective jigs, tacked, and welded. This was especially important for this jig design due to the fact not all tubes were being constrained by the jig.

Our assembly plan and tube mitering/feathering both contributed to gap minimization as well.

Phase One: tubes and jigs flush to the table + front bulkhead

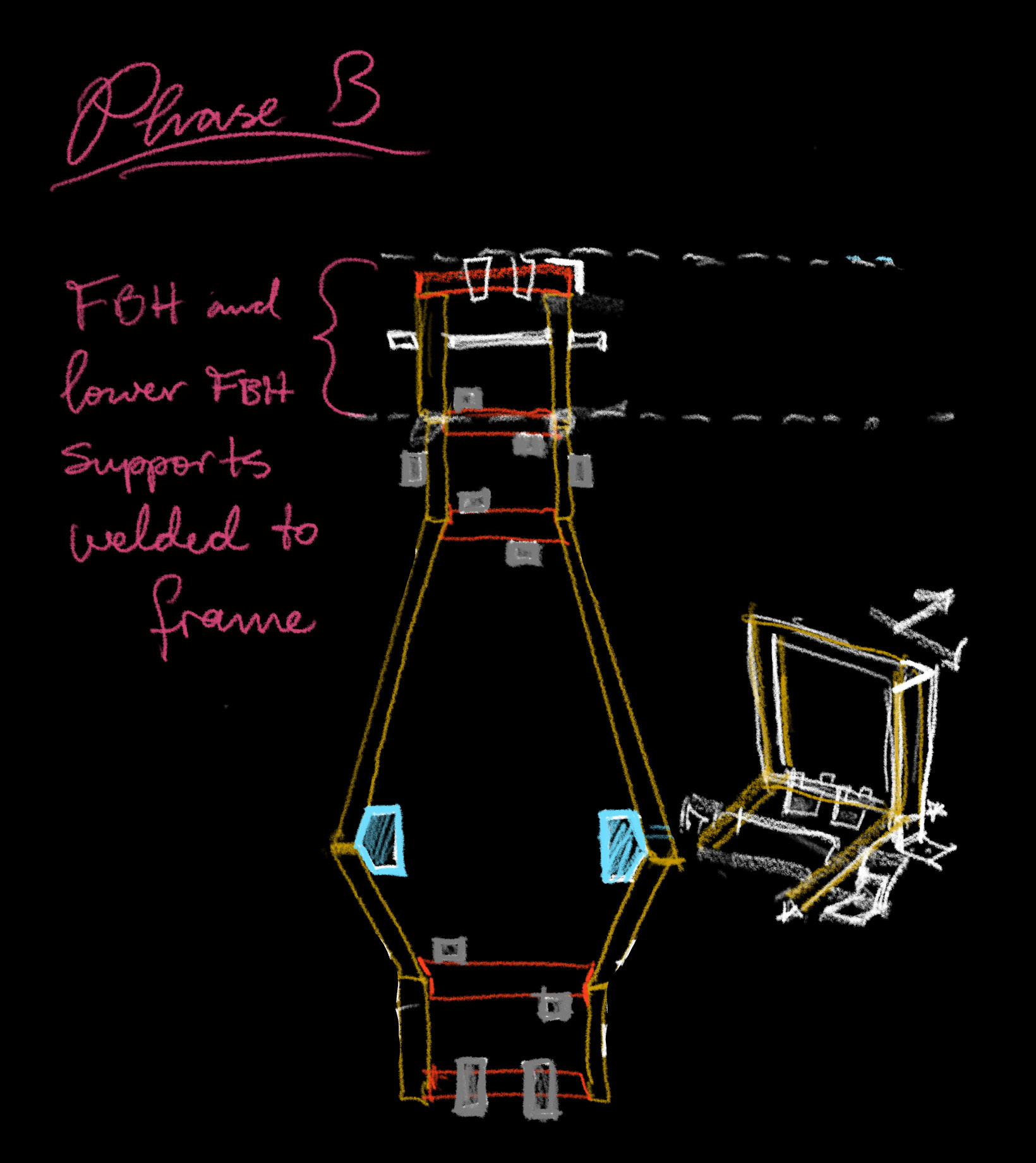

Phase Two: front bulkhead, roll hoops, rear box

Phase Three: diagonal tubes in front and rear

Phase Four: side impact structure tubes

Phase Five: remainder of side impact structure tubes

Phase Six: front roll hoop rear supports

Phase Seven: rear decoupled node tubes

Phase Eight: front decoupled node tubes

In the ideation process of designing a jig, we explored different materials taking into consideration the cost of material, time to manufacture, and ability to keep tight tolerances.

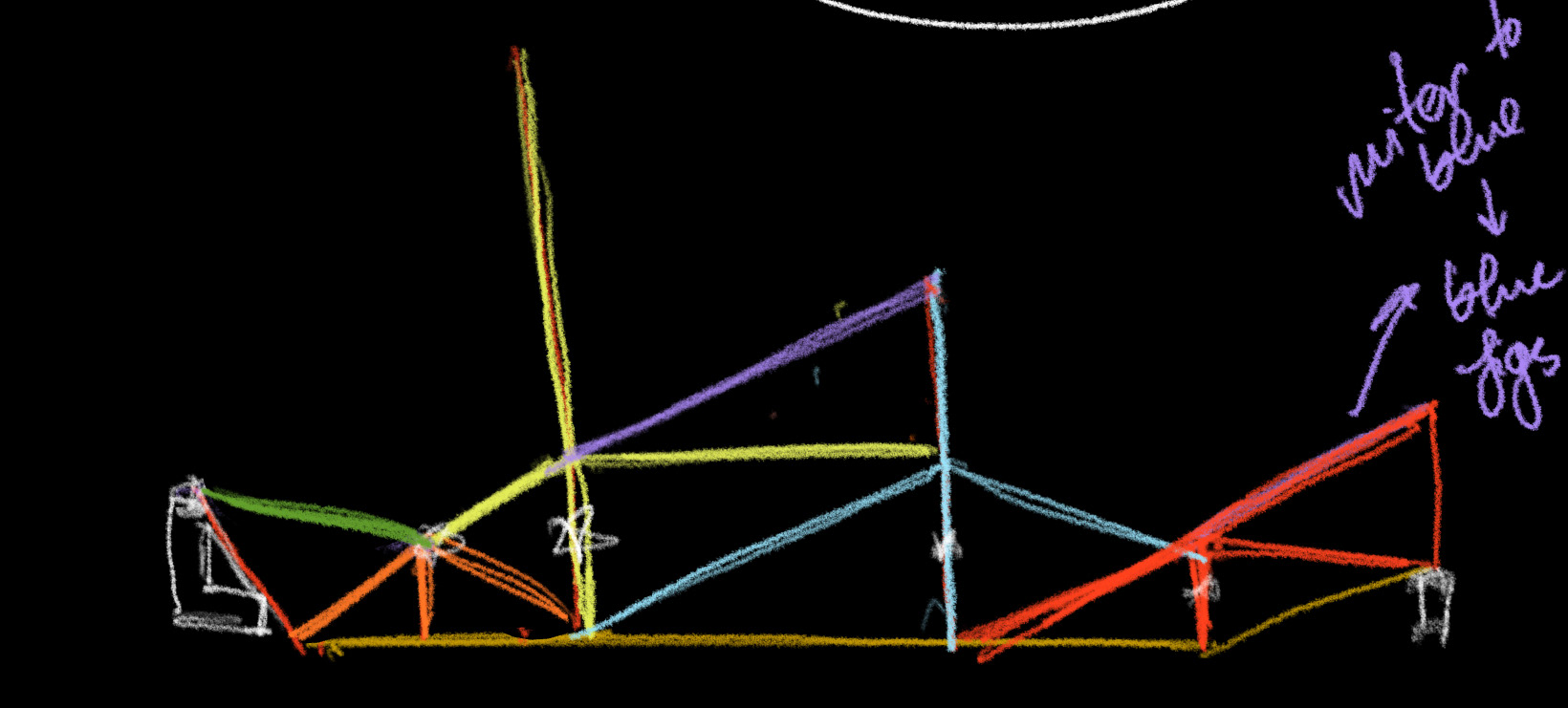

This year we designed a disassembly plan that made it easier to move throughout the manufacturing process without affecting the accuracy of the frame itself. This was especially important because we share a space with our combustion team and needed to move our frame so they could use the optical table.

The table flush jigs also made it easy to move the frame around freely without having to actually remove the jigs. Additionally, the disassembly process didn't require us to destroy the jig which could affect frame tube placement

R e s u l t s

Increased accuracy of node location by 30%, 90% within 0.050

Partial removability and minimal components improved the ease and quality of welds

S a n d i n g a n d P a i n t i n g

Photo Gallery: Frame and Control Arm Welding

2 0 2 4